What are the benefits of choosing an all-in-one leather punching and sewing machine for high-end leather production?

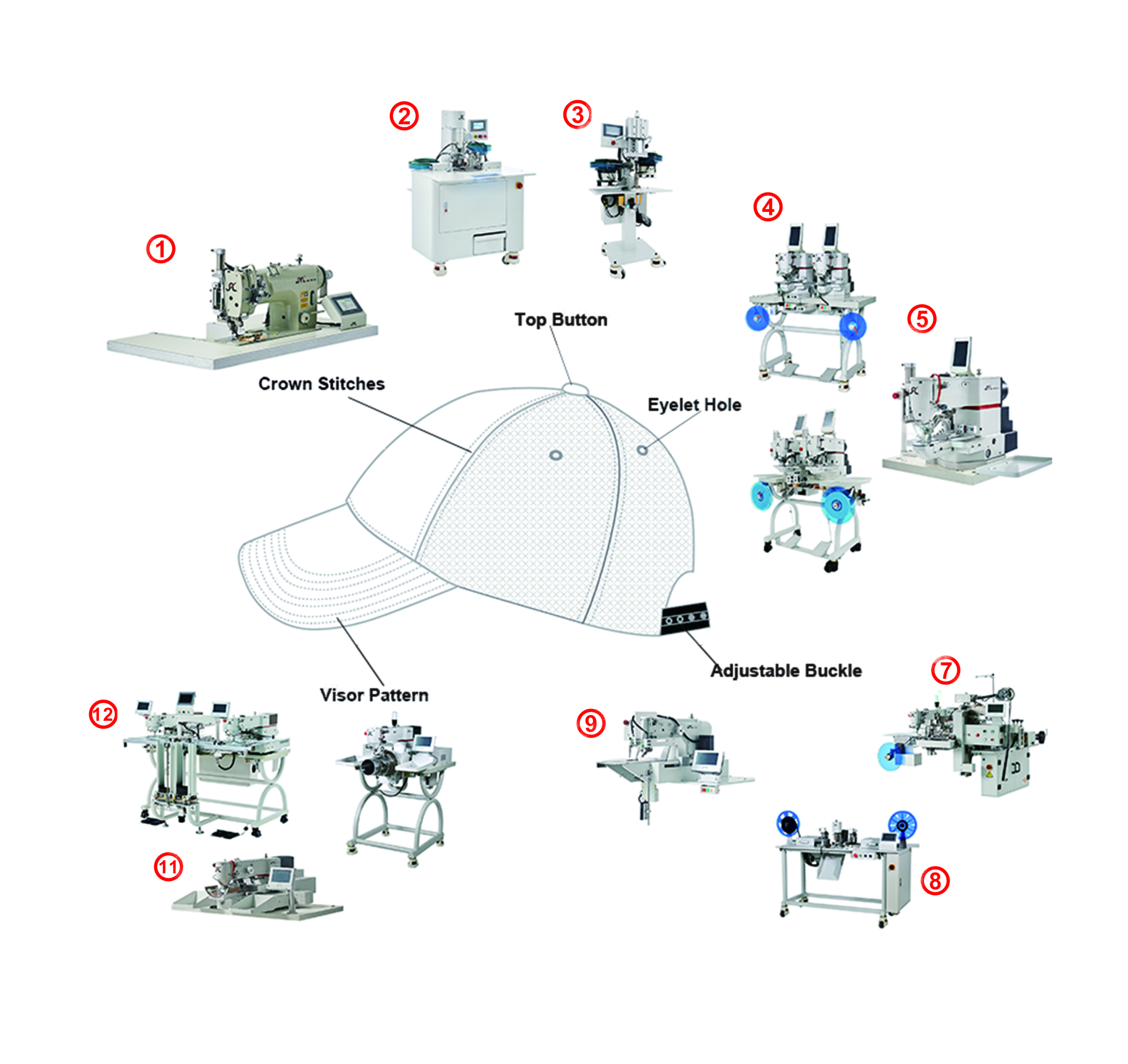

Leatherworking and production is a craft that requires several specialized machines for different processes. Cutting, punching, and stitching leather are some of the most common and essential steps in creating leather goods. However, using separate machines for each process can be costly, time-consuming, and inefficient. That is why many leather producers are opting for an all-in-one machine that combines these processes into one.

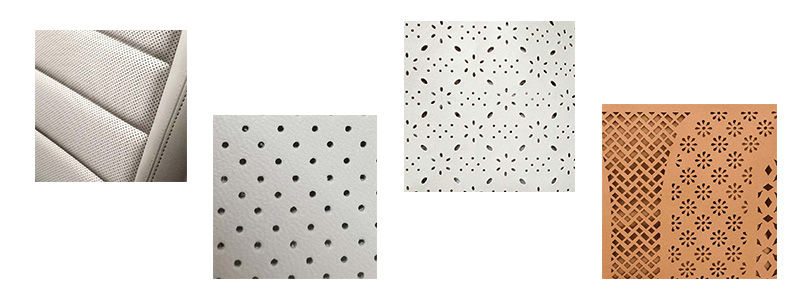

An all-in-one leather machine is a device that can punch holes and sew stitches on leather materials. It is designed to handle various types of leather, such as cowhide, sheepskin, pigskin, and synthetic leather. It can also work on different thicknesses and shapes of leather, depending on the model and settings. An all-in-one leather machine provides significant benefits for high-volume or high-end leather producers who want to improve their efficiency, quality, output, and capabilities.

One of the main benefits of an all-in-one leather machine is that it saves space in production facilities by consolidating multiple machines into one. This reduces the need for extra equipment, wiring, and installation. It also makes it easier to move the machine around or transport it to different locations.

Another benefit of an all-in-one leather machine is that it streamlines the workflow since workers can punch and stitch on the same machine. This eliminates the need to transfer the leather materials from one machine to another, which can be tedious and prone to errors. It also reduces the risk of damaging or losing the leather materials during the transfer.

A third benefit of an all-in-one leather machine is that it ensures consistent quality with computerized control of punching and stitching. The automated punching and stitching machine can be programmed to follow precise specifications and patterns for each product. It can also adjust the speed, pressure, and tension of the punching and stitching according to the type and thickness of the leather. This results in uniform and flawless products that meet high standards.

A fourth benefit of an all-in-one leather machine is that it is programmable to handle repetitive tasks or customize designs. The computerized leather machine can store multiple presets and templates for different products and styles. It can also create new designs or modify existing ones using software or touch screen interfaces. This allows the producer to create a variety of products with ease and flexibility.

A fifth benefit of an fully automation all-in-one leather machine is that it produces higher output for increased production capacity. The leather Processing machine can operate faster and longer than separate machines without compromising quality or performance. It can also handle larger volumes of leather materials without requiring frequent refills or replacements. This enables the producer to meet higher demands and deadlines.

A sixth benefit of an all-in-one leather machine is that some models include additional capabilities like laser cutting. Laser cutting is a process that uses a laser beam to cut or engrave shapes or patterns on leather materials. It can create intricate and detailed designs that are difficult or impossible to achieve with conventional methods. It can also enhance the appearance and value of the products.

A seventh benefit of an all-in-one leather machine is that it reduces costs associated with multiple machines for purchase, maintenance, and operation. Buying one machine instead of several can save money on initial investment, shipping, installation, and taxes. Maintaining one machine instead of several can save money on repairs, parts, service, and cleaning. Operating one machine instead of several can save money on electricity, fuel, labor, and waste.

An eighth benefit of an all-in-one leather punching machine is that it offers better accuracy and precision with digitally controlled punching and sewing. The automatic leather sewing machine can punch holes and sew stitches with exact measurements and alignments. It can also correct any errors or deviations automatically or manually. This minimizes the chances of mistakes or defects that can affect the quality or functionality of the products.

A ninth benefit of an all-in-one leather machine is that it is ideal for complex tasks like stitching small leather goods or upholstery. Small leather goods are products that are made from small pieces of leather, such as wallets, belts, keychains, and cases. Upholstery is a process that involves covering furniture or other items with fabric or leather materials. These tasks require fine and delicate punching and stitching that are difficult or impractical to do with separate machines.

In conclusion, all-in-one leather punching sewing machines provide many benefits for high-volume or high-end leather producers who want to improve their efficiency, quality, output, and capabilities. They save space in production facilities by consolidating multiple machines into one. They streamline workflow since workers can punch and stitch on one machine. They ensure consistent quality with computerized control of punching and stitching. They are programmable to handle repetitive tasks or customize designs. They produce higher output for increased production capacity. They include additional capabilities like laser cutting. They reduce costs associated with multiple machines for purchase, maintenance, and operation. They offer better accuracy and precision with digitally controlled punching and sewing. They are ideal for complex tasks like stitching small leather goods or upholstery. All-in-one leather machines are optimal for producers focused on high-end leather goods who want to create products that are durable, beautiful, and valuable. The investment pays for itself through increased production capacity and consistency.