Post Bed Sewing Machine Buying Guide

The most sought-after sewing machines used for clothing and footwear manufacture is the post-bed machine, that has a vertical frame which allows the user to quickly move the item being stitched. Post bed machines usually have an incline foot, or roller feed that functions as an element of feeding that is able to compress and guide the fabric that is being stitched and permits greater ease of moving the product by sewing around edges and in precise places.

Sewing machines for post bed are often used in the following scenarios:

- Sneaker and footwear construction

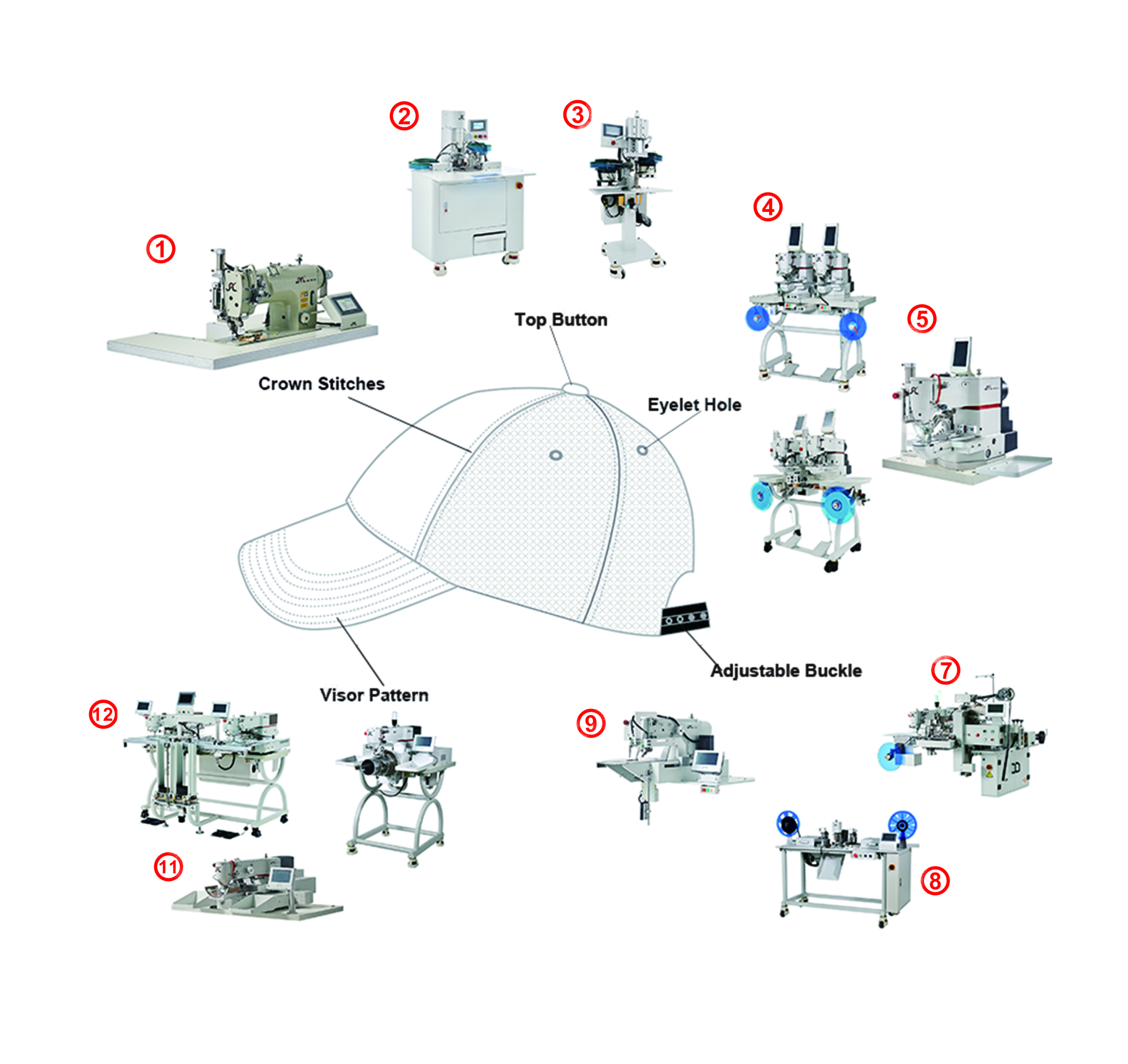

- Making patches for clothing and hats

- Leather products

- Garment sews and repairs

When sewing the upper part of sneakers the post bed’s wide sewing space will allow the user to rotate and adjust the layers that are being stitched without interruption from any other component that is part. The roller foot gives more visibility while sewing your stitches around the edges and edges of the fabric.

When sewing patches to garments and hats users can effortlessly move the hat around without the need to fold or compress it in the course of sewing. The roller will compress the patch while stitching a border stitch that can secure it to its hat.

- Post beds are accessible that have the following feed mechanisms

- Drop feed for the roller foot.

- Upper and lower rollers that are synchronized feed

- Walking on the foot or feeding a compound

- Foot with Roller Foot that has a Drop Feed

Drop feed is by far the most popular kind of feed mechanism used in the industrial and home sewing machines This is because the feed dog presses on the lower part of the material , and then advances through the sewing machine as sewing the material. The roller foot is compressed and does the job of guiding the product. This lets you move more easily the material as well as sewing along edges and sewing into specific regions.

The feeding system is suitable for all kinds of the production of apparel and footwear (leather faux leather, suede, denim foams, canvas, plastics,).

Synchronized Upper and Lower Roller Feed:

A synchronized lower and upper rolling feed feeding mechanism that uses the roller foot which is driven by gears and linked to the feed dog that moves the material through the machine while it is being stitched. The roller foot is compressed and works to guide the product. It lets you move more easily the item as well as sewing around edges and sewing in precise regions.

It is suitable for all types of materials that are used in apparel and footwear production (leather faux leather, suede, canvas, denim, foams and synthetic materials) It also is superior to dropping feed mechanisms when sewing materials that are significantly bulkier or thicker or when the wearer wants to sew different kinds of materials that could be thicker or multi-layered.

Walking Foot or Compound Feed:

A walking foot, also known as a the compound feed, is an mechanism for feeding in which the presser feet “walk” into the fabric through the machine and the needle moves between the two with the inside foot presser to assist in feeding the material. Compound walking foot machines maintain constant downward pressure on the fabric, preventing the multi-layered materials from shifting during sewing.

The feeding system is suitable to the majority of kinds of materials that are used in apparel and footwear production. It is particularly useful for sewing very thick or multi-layered products like straps, belts, upholstery items, leather, and much more.

It is the JYLsew 810 fabric is suitable for all kinds of manufacturing of clothing and footwear (leather faux leather, suede, denim foams, canvas plastics, synthetic materials).

The JYLsew 830 can also be used with all kinds of fabrics used in clothing and footwear production. It has an advantages over the 810 in the event that users want to sew more thick and multi-layered materials as well as other kinds of items. The 830 is able to be used to sew 3/8″ thick fabric and use up to a size #22 needle and thread size #138.

The JYLsew 860 is also suitable for all kinds of fabrics used in clothing and footwear production. It also offers a stronger feeding mechanism over the 810 and 830. The 860 is able to sew as much as 3/8″ thick fabric and make use of larger needles as well as thread size. The 860 is equipped with a larger bobbin size. The 860 can be used any size up to #24 needles and thread size #138.

What exactly is the purpose of “PRO” package?

Available in conjunction with the JYLsew 810 and 830 models, the PRO package comes with:

Automatic Needle Position System- specifically designed to increase efficiency The SmartServo-NP motor will immediately stop the needle from down position after the pedal on the operation is released which allows the user to move the device to sew a 90 degree corner.

Swing Down Roller Edge GuideIt is adjustable and simple to lift and move away from the way, the guide for the edge of the roller helps to guide the material into straight lines, thus increasing the accuracy of stitching.

Flatbed Table Attachment: the attachment can be placed directly over the arm of the cylinder, turning it into a flatbed machine to make it easier to sew flat items such as belts and wallets.

Speed Reducer Pulley – The speed reducer pulley can be placed in conjunction in conjunction with the variable-speed Servo motor which reduces the speed of sewing to less than one sewing per second.

The rubber Roller Foot- Helps alleviate the marks of feet with soft leather.

Accessory Package: an accessory package that includes 1 spool in size #69 needles 3 needle packages (size #18) 8 Bobbins.

Do I require a speed reduction device?

For those who are just beginning and who require the slowest speed of sewing, a pulley with a speed reducer is available from our experts to add torque and reduce the speed of the machine. The motor already installed on the machine is capable of very low sewing speeds (approximately 2-stitch per second). A speed reducer can further reduce the speed of sewing to about 1-stitch per second.

If you require assistance in selecting the best sewing machine to meet your needs please reach to our friendly team of experts for guidance!