Maximizing Production Efficiency with a Full Automatic Leather Punching Sewing Machine

Leather is one of the most versatile and durable materials used for various products, such as footwear, clothing, furniture, bags, and accessories. However, leather production is also a complex and labor-intensive process that involves many steps, such as cutting, punching, sewing, and finishing. To achieve high-quality leather products, each step requires precision, consistency, and speed.

Production efficiency is a key factor that determines the success and profitability of any leather manufacturer. It refers to the ratio of output to input in a production process. The higher the production efficiency, the more output can be produced with the same or less input. Production efficiency can be improved by reducing waste, optimizing resources, increasing productivity, and enhancing quality.

One of the most effective ways to improve production efficiency in leather manufacturing is to use full automatic leather punching sewing machines. These machines are designed to perform both punching and sewing operations on leather materials with high speed and accuracy. They can replace manual or semi-automatic methods that are slow, inconsistent, and prone to errors.

In this article, we will explain how full automatic leather punching sewing machines work and how they differ from traditional methods. We will also discuss the features and benefits of these machines and how they can impact production efficiency. Finally, we will provide some tips on how to maximize production efficiency with full automatic leather punching sewing machines and what to expect from the future of leather production with this technology.

What is the Process of full automatic leather punching sewing machine?

Before we dive into the details of full automatic leather punching sewing machines, let us first understand the process of leather punching and sewing and how it is done traditionally.

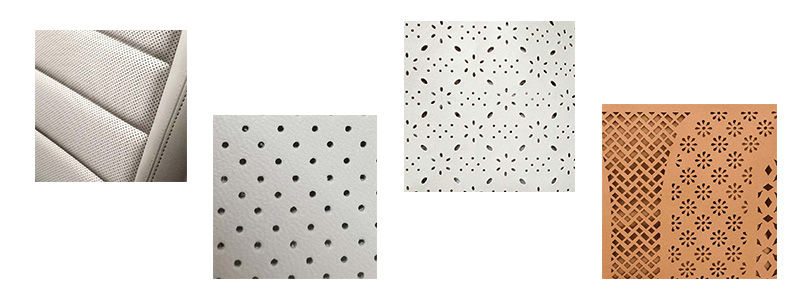

Leather punching is the process of creating holes or patterns on leather materials using various tools, such as punches, dies, chisels, or needles. Leather punching is usually done before sewing to prepare the leather for stitching or to create decorative effects.

Leather sewing is the process of joining two or more pieces of leather together using thread and needles. Leather sewing can be done by hand or by machine. Hand sewing is more suitable for small or delicate projects that require more control and flexibility. Machine sewing is more suitable for large or repetitive projects that require more speed and consistency.

Traditional methods of leather punching and sewing involve manual or semi-automatic operations that require skilled workers and specialized equipment. For example, manual punching requires workers to use hammers and punches to create holes on leather by hand. Semi-automatic punching requires workers to use hydraulic or pneumatic presses to punch holes on leather using dies or templates. Manual sewing requires workers to use needles and thread to stitch leather by hand using various techniques, such as saddle stitch or whip stitch. Semi-automatic sewing requires workers to use electric or mechanical sewing machines to stitch leather using pre-programmed patterns or settings.

These traditional methods have some limitations and drawbacks that affect production efficiency. For instance:

- Manual or semi-automatic methods are time-consuming and labor-intensive. They require workers to perform multiple tasks, such as measuring, marking, cutting, aligning, punching, sewing, trimming, etc. These tasks can take hours or days to complete depending on the complexity and quantity of the project.

- Manual or semi-automatic methods are inconsistent and prone to errors. They depend on the skill and experience of the workers and the quality and condition of the equipment. Human errors, such as miscalculations, misalignments, misplacements, etc., can result in defective or substandard products that need to be repaired or discarded.

- Manual or semi-automatic methods are wasteful and inefficient. They generate a lot of scrap material that cannot be reused or recycled. They also consume a lot of energy and resources, such as electricity, water, chemicals, etc., that increase production costs and environmental impact.

How do full automatic leather punching sewing machines work?

Full automatic leather punching sewing machines are advanced machines that can perform both punching and sewing operations on leather materials with high speed and accuracy. They can replace manual or semi-automatic methods that are slow, inconsistent, and prone to errors.

Full automatic leather punching sewing machines work by using computerized systems that control the movement and operation of the machine components. The main components of a full automatic leather punching sewing machine are:

- A feeding system that transports the leather material into the machine

- A punching system that creates holes or patterns on the leather material using laser beams or rotary blades

- A sewing system that stitches the leather material together using needles and thread

- A cutting system that trims the excess material from the finished product

- A control system that monitors and regulates the machine functions

The process of using a full automatic leather punching sewing machine is simple and straightforward. The user only needs to load the leather material into the feeding system, select the desired punching and sewing parameters from a touch screen panel or a computer software program, and start the machine. The machine will automatically perform the punching and sewing operations according to the user’s specifications. The user can also adjust or modify the parameters during the process if needed. The finished product will be automatically ejected from the cutting system.

Key differences between traditional methods and automation

The main differences between traditional methods and full automatic leather punching sewing machines are:

- Speed: Full automatic leather punching sewing machines can perform punching and sewing operations much faster than manual or semi-automatic methods. They can process large quantities of leather materials in a short time, reducing production time and increasing output.

- Accuracy: Full automatic leather punching sewing machines can perform punching and sewing operations with high precision and consistency. They can create holes or patterns with exact dimensions and locations, and stitch leather materials with uniform tension and spacing. They can also avoid human errors, such as miscalculations, misalignments, misplacements, etc., that can cause defects or variations in the products.

- Waste: Full automatic leather punching sewing machines can perform punching and sewing operations with minimal waste and material optimization. They can use laser beams or rotary blades to punch holes or patterns on leather materials without generating any scrap material. They can also use needles and thread to stitch leather materials without leaving any loose ends or excess thread. They can also trim the excess material from the finished product with precise cutting systems, reducing material loss and waste disposal costs.

- Energy: Full automatic leather punching sewing machines can perform punching and sewing operations with low energy consumption and resource utilization. They can use laser beams or rotary blades to punch holes or patterns on leather materials without using any water, chemicals, or heat. They can also use needles and thread to stitch leather materials without using any electricity, gas, or oil. They can also reduce the energy consumption of the machine components by using intelligent programming capabilities that optimize the machine functions.

Features of Full Automatic Leather Punching Sewing Machines

Full automatic leather punching sewing machines have many features that make them superior to traditional methods. Some of these features are:

- High-speed operation: Full automatic leather punching sewing machines can operate at high speeds that range from 200 to 1000 stitches per minute, depending on the machine model and configuration. This allows them to process large quantities of leather materials in a short time, reducing production time and increasing output.

- Precise punching: Full automatic leather punching sewing machines can create holes or patterns on leather materials with high precision and consistency. They can use laser beams or rotary blades to punch holes or patterns on leather materials with exact dimensions and locations. They can also adjust the size, shape, depth, and density of the holes or patterns according to the user’s specifications.

- Intelligent programming: Full automatic leather punching sewing machines have intelligent programming capabilities that allow the user to control and customize the machine functions. The user can select the desired punching and sewing parameters from a touch screen panel or a computer software program, such as the hole or pattern size, shape, depth, density, location, direction, etc., and the stitch type, length, width, tension, spacing, etc. The user can also adjust or modify the parameters during the process if needed. The machine will automatically perform the punching and sewing operations according to the user’s specifications.

- Fault detection: Full automatic leather punching sewing machines have fault detection systems that monitor and detect any errors or malfunctions in the machine components. The machine will automatically stop the operation and alert the user if any fault is detected. The user can then troubleshoot and fix the problem before resuming the operation. This prevents damage to the machine or the product and ensures safety and quality.

- Easy maintenance: Full automatic leather punching sewing machines have easy maintenance systems that facilitate the cleaning and servicing of the machine components. The machine has a self-cleaning function that removes any dust or debris from the machine parts after each operation. The machine also has a self-lubricating function that applies oil to the machine parts periodically to prevent wear and tear. The user only needs to perform regular inspections and replacements of some consumable parts, such as needles, thread, blades, etc.

The Impact of Full Automation on Production Efficiency

Full automation has a significant impact on production efficiency in leather manufacturing. By using full automatic leather punching sewing machines, leather manufacturers can achieve:

- Speed and consistency: Full automatic leather punching sewing machines can perform punching and sewing operations much faster than manual or semi-automatic methods. They can process large quantities of leather materials in a short time, reducing production time and increasing output. They can also perform punching and sewing operations with high precision and consistency. They can create holes or patterns with exact dimensions and locations, and stitch leather materials with uniform tension and spacing. They can also avoid human errors, such as miscalculations, misalignments, misplacements, etc., that can cause defects or variations in the products.

- Waste reduction: Full automatic leather punching sewing machines can perform punching and sewing operations with minimal waste and material optimization. They can use laser beams or rotary blades to punch holes or patterns on leather materials without generating any scrap material. They can also use needles and thread to stitch leather materials without leaving any loose ends or excess thread. They can also trim the excess material from the finished product with precise cutting systems, reducing material loss and waste disposal costs.

- Energy saving: Full automatic leather punching sewing machines can perform punching and sewing operations with low energy consumption and resource utilization. They can use laser beams or rotary blades to punch holes or patterns on leather materials without using any water, chemicals, or heat. They can also use needles and thread to stitch leather materials without using any electricity, gas, or oil. They can also reduce the energy consumption of the machine components by using intelligent programming capabilities that optimize the machine functions.

Case study: Comparison of traditional methods vs. full automatic methods in a real production scenario

To illustrate the impact of full automation on production efficiency, let us compare the traditional methods and the full automatic methods in a real production scenario. Suppose a leather manufacturer wants to produce 1000 leather jackets with a simple hole pattern on the front and back panels and a basic stitch type on the seams. The leather material used is cowhide with a thickness of 1.5 mm and a width of 1.2 m. The hole pattern has a diameter of 5 mm and a density of 10 holes per 10 cm^2. The stitch type is lockstitch with a length of 3 mm and a width of 2 mm.

Using traditional methods, the manufacturer would need to perform the following steps:

- Cutting: The manufacturer would need to use a cutting machine or a knife to cut the leather material into the required shapes and sizes for the jacket panels. This would take about 10 minutes per panel, resulting in a total cutting time of 20,000 minutes or 333 hours for 1000 jackets.

- Punching: The manufacturer would need to use a hydraulic or pneumatic press to punch holes on the leather panels using dies or templates. This would take about 5 minutes per panel, resulting in a total punching time of 10,000 minutes or 167 hours for 1000 jackets.

- Sewing: The manufacturer would need to use an electric or mechanical sewing machine to stitch the leather panels together using needles and thread. This would take about 15 minutes per jacket, resulting in a total sewing time of 15,000 minutes or 250 hours for 1000 jackets.

- Trimming: The manufacturer would need to use a cutting machine or a knife to trim the excess material from the finished jackets. This would take about 5 minutes per jacket, resulting in a total trimming time of 5,000 minutes or 83 hours for 1000 jackets.

The total production time for 1000 jackets using traditional methods would be 50,000 minutes or 833 hours.

Using full automatic methods, the manufacturer would need to perform the following steps:

- Loading: The manufacturer would need to load the leather material into the feeding system of the full automatic leather punching sewing machine. This would take about 1 minute per panel, resulting in a total loading time of 2,000 minutes or 33 hours for 1000 jackets.

- Punching and sewing: The manufacturer would need to select the desired punching and sewing parameters from a touch screen panel or a computer software program and start the machine. The machine would automatically perform the punching and sewing operations according to the user’s specifications. This would take about 3 minutes per jacket, resulting in a total punching and sewing time of 3,000 minutes or 50 hours for 1000 jackets.

- Ejecting: The manufacturer would need to unload the finished jackets from the cutting system of the full automatic leather punching sewing machine. This would take about 1 minute per jacket, resulting in a total ejecting time of 1,000 minutes or 17 hours for 1000 jackets.

The total production time for 1000 jackets using full automatic methods would be 6,000 minutes or 100 hours.

The comparison shows that using full automatic methods can reduce the production time by 87% compared to using traditional methods. This means that the manufacturer can produce more jackets in less time with full automation, increasing production efficiency and output.

Maximizing Production Efficiency

To maximize production efficiency with full automatic leather punching sewing machines, leather manufacturers need to consider some factors and implement some strategies. Some of these are:

- Integrating full automatic machines into the existing production line: Leather manufacturers need to plan and design how to integrate full automatic machines into their existing production line without disrupting their current workflow and operations. They need to consider factors such as space availability, layout configuration, compatibility with other machines and equipment, safety measures, etc. They also need to test and evaluate the performance and functionality of the full automatic machines before fully implementing them into their production line.

- Training personnel to operate and maintain the machines: Leather manufacturers need to train their personnel to operate and maintain the full automatic machines properly and efficiently. They need to provide them with adequate instructions and guidance on how to use the touch screen panel or computer software program to select and adjust the punching and sewing parameters, how to load and unload the leather material into and from the machine, how to troubleshoot and fix any errors or malfunctions in the machine components, how to perform regular inspections and replacements of the consumable parts, etc. They also need to monitor and evaluate the performance and productivity of their personnel and provide them with feedback and improvement suggestions.

- Utilizing software capabilities for process optimization: Leather manufacturers need to utilize the software capabilities of the full automatic machines for process optimization. They need to use the software program to create and store various punching and sewing patterns and settings that suit their production needs and preferences. They also need to use the software program to analyze and optimize the machine functions, such as the speed, accuracy, waste, energy, etc., of the punching and sewing operations. They also need to use the software program to track and manage the production data, such as the quantity, quality, time, cost, etc., of the products.

The Future of Leather Production with Full Automatic Machines

Full automatic leather punching sewing machines are a revolutionary technology that can transform the leather production industry. They can offer many benefits and impacts for leather manufacturers, such as:

- Further technological advancements: Full automatic leather punching sewing machines are constantly evolving and improving with new features and functions that can enhance their performance and functionality. For example, future full automatic machines may use more advanced laser or blade technologies that can create more complex and intricate holes or patterns on leather materials. They may also use more sophisticated software programs that can provide more options and flexibility for punching and sewing parameters. They may also use more intelligent systems that can learn from the user’s behavior and preferences and adapt accordingly.

- Potential economic impact: Full automatic leather punching sewing machines can have a positive economic impact for leather manufacturers. They can reduce production costs by saving time, labor, material, energy, and resources. They can also increase production output by increasing speed, accuracy, consistency, and quality. They can also improve production competitiveness by offering more variety and customization for leather products. They can also create new market opportunities by expanding their customer base and reaching new segments.

- Potential environmental impact: Full automatic leather punching sewing machines can have a positive environmental impact for leather manufacturers. They can reduce environmental pollution by minimizing waste generation and disposal. They can also reduce greenhouse gas emissions by lowering energy consumption and resource utilization. They can also promote sustainability by optimizing material usage and recycling.

However, full automation also poses some challenges and concerns for leather manufacturers, such as:

- Job displacement: Full automation may result in job displacement for some workers who perform manual or semi-automatic tasks in leather production. These workers may lose their jobs or have to shift to other roles or sectors that require different skills or qualifications. This may cause social and economic problems, such as unemployment, income inequality, poverty, etc.

- Investment costs: Full automation may require high investment costs for leather manufacturers who want to adopt full automatic machines into their production line. These costs may include purchasing, installing, operating, maintaining, upgrading, etc., of the full automatic machines. These costs may be difficult to afford or recover for some small or medium-sized leather manufacturers who have limited financial resources or market share.

- Ethical issues: Full automation may raise some ethical issues for leather manufacturers who use full automatic machines in their production line. These issues may include the responsibility and accountability for the quality and safety of the products produced by the full automatic machines, the protection and privacy of the data collected and stored by the software programs of the full automatic machines, the fairness and transparency of the decision-making processes of the intelligent systems of the full automatic machines, etc.

Conclusion

Full automatic leather punching sewing machines are a powerful technology that can improve production efficiency in leather manufacturing. They can perform both punching and sewing operations on leather materials with high speed and accuracy. They can also reduce waste, optimize resources, increase productivity, and enhance quality.

By using full automatic leather punching sewing machines, leather manufacturers can achieve many benefits and impacts, such as:

- Reducing production time by 87% compared to traditional methods

- Saving time, labor, material, energy, and resources

- Increasing output, variety, customization, competitiveness, and market opportunities

- Minimizing waste generation and disposal

- Lowering energy consumption and resource utilization

- Optimizing material usage and recycling

- Reducing environmental pollution and greenhouse gas emissions

- Promoting sustainability

However, full automation also poses some challenges and concerns for leather manufacturers, such as:

- Job displacement

- Investment costs

- Ethical issues

Therefore, leather manufacturers need to consider these factors carefully before adopting full automatic machines into their production line. They also need to implement some strategies to maximize production efficiency with full automatic machines, such as:

- Integrating full automatic machines into the existing production line

- Training personnel to operate and maintain the machines

- Utilizing software capabilities for process optimization

Full automatic leather punching sewing machines are a promising technology that can revolutionize the leather production industry. They can offer a new way of creating high-quality leather products with efficiency and innovation.