[av_heading heading=’The Fourth Generation Sewing Machine – Creating A New Era Of Automatic Production Of Garment Enterprises’ tag=’h2′ style=’blockquote modern-quote modern-centered’ subheading_active=” show_icon=” icon=’ue800′ font=’entypo-fontello’ size=” av-medium-font-size-title=” av-small-font-size-title=” av-mini-font-size-title=” subheading_size=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” icon_size=” av-medium-font-size-1=” av-small-font-size-1=” av-mini-font-size-1=” color=” custom_font=” subheading_color=” seperator_color=” icon_color=” margin=” margin_sync=’true’ padding=’10’ icon_padding=’10’ headline_padding=” headline_padding_sync=’true’ link=” link_target=” id=” custom_class=” template_class=” element_template=” one_element_template=” av_uid=’av-l3cr8w4v’ sc_version=’1.0′ admin_preview_bg=”][/av_heading]

[av_social_share title=” buttons=’custom’ btn_action=” share_facebook=’aviaTBshare_facebook’ share_twitter=’aviaTBshare_twitter’ share_whatsapp=’aviaTBshare_whatsapp’ share_pinterest=’aviaTBshare_pinterest’ share_reddit=’aviaTBshare_reddit’ share_linkedin=’aviaTBshare_linkedin’ share_vk=’aviaTBshare_vk’ yelp_link=’https://www.yelp.com’ facebook_profile=” twitter_profile=” whatsapp_profile=” pinterest_profile=” reddit_profile=” linkedin_profile=” tumblr_profile=” vk_profile=” mail_profile=” yelp_profile=” five_100_px_profile=” behance_profile=” dribbble_profile=” flickr_profile=” instagram_profile=” skype_profile=” soundcloud_profile=” vimeo_profile=” xing_profile=” youtube_profile=” style=’av-social-sharing-box-circle’ alignment=’av-social-sharing-center’ alb_description=” id=” custom_class=” template_class=” element_template=” one_element_template=” av_uid=’av-3a5yms’ sc_version=’1.0′ admin_preview_bg=”]

[av_textblock textblock_styling_align=” textblock_styling=” textblock_styling_gap=” textblock_styling_mobile=” size=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” font_color=” color=” id=” custom_class=” template_class=” element_template=” one_element_template=” av_uid=’av-l6xawim6′ sc_version=’1.0′ admin_preview_bg=”][/av_textblock]

[av_one_full first min_height=” vertical_alignment=’av-align-top’ space=” row_boxshadow=” row_boxshadow_color=” row_boxshadow_width=’10’ custom_margin=” margin=’0px’ mobile_breaking=” mobile_column_order=” min_col_height=” padding=” svg_div_top=” svg_div_top_color=’#333333′ svg_div_top_width=’100′ svg_div_top_height=’50’ svg_div_top_max_height=’none’ svg_div_top_flip=” svg_div_top_invert=” svg_div_top_front=” svg_div_top_opacity=” svg_div_top_preview=” svg_div_bottom=” svg_div_bottom_color=’#333333′ svg_div_bottom_width=’100′ svg_div_bottom_height=’50’ svg_div_bottom_max_height=’none’ svg_div_bottom_flip=” svg_div_bottom_invert=” svg_div_bottom_front=” svg_div_bottom_opacity=” svg_div_bottom_preview=” border=” border_style=’solid’ border_color=” radius=” column_boxshadow=” column_boxshadow_color=” column_boxshadow_width=’10’ background=’bg_color’ background_color=” background_gradient_direction=’vertical’ background_gradient_color1=’#000000′ background_gradient_color2=’#ffffff’ background_gradient_color3=” src=” background_position=’top left’ background_repeat=’no-repeat’ highlight=” highlight_size=” animation=” link=” linktarget=” link_hover=” title_attr=” alt_attr=” mobile_display=” mobile_col_pos=’0′ id=” custom_class=” template_class=” aria_label=” av_uid=’av-1o12n’ sc_version=’1.0′]

[av_textblock textblock_styling_align=” textblock_styling=” textblock_styling_gap=” textblock_styling_mobile=” size=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” font_color=” color=” id=” custom_class=” template_class=” element_template=” one_element_template=” av_uid=’av-l3cr6229′ sc_version=’1.0′ admin_preview_bg=”]

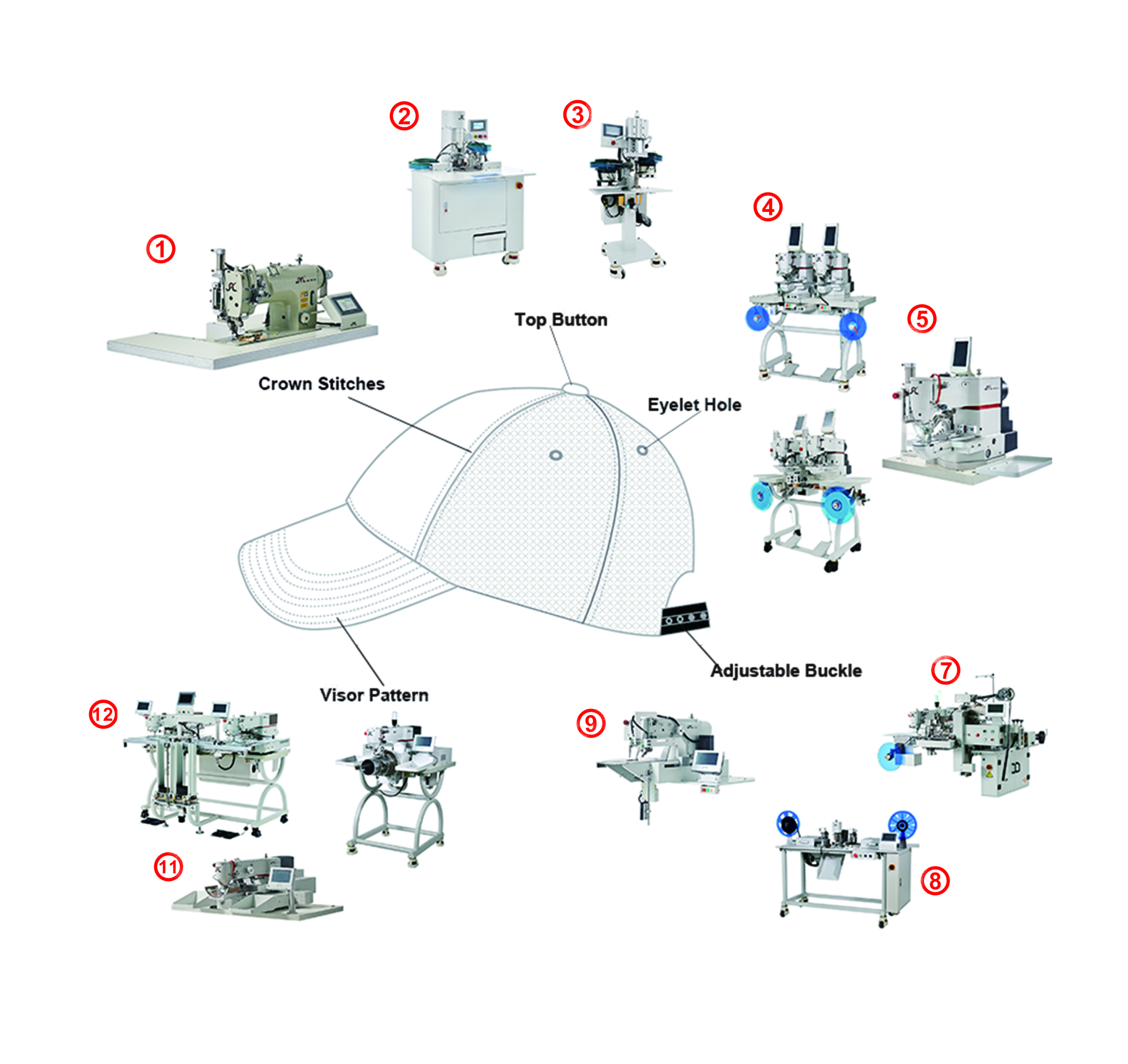

The fourth generation sewing machine is a set of computer numerical control sewing equipment. Its characteristic is that the stitching is completely automated, without relying on the operator’s techniques and skills; the bridge structure is no longer limited to one person and one machine, and can be operated by one person and multiple machines.

Since it was identified as an international leading scientific and technological achievement in 2013 and won the honorary title of the first prize of CISMA excellent product of China Sewing Machinery Association, the fourth-generation sewing machine developed by JYL has been widely used and promoted. The effect is quite satisfactory and has been recognized by the industry. The fourth generation of sewing machines has created a new era of automated production in garment enterprises.

Automatic Velcro Feeding and sewing machine

The Fourth Generation Sewing Machine – Creating A New Era Of Automatic Production Of Garment Enterprises

Save manpower and reduce costs

The fourth-generation sewing machine is used to sew double-layer ultra-thin fabrics, which is smooth and wrinkle-free, and the stitch tension on both sides is even. It can also sew thick materials, and the design of the template fixture is not restricted by height, and it is richer in tension and widely adaptable. Collars, cuffs, epaulets, etc. need to be sewn and trimmed, and sewing + cutting can be completed at one time. It can also be sewn first and then cut, the whole width is sewn and then automatically cut, and the patch pattern is automatically sewn. The template is automatically loaded and unloaded without manual plate changing, which minimizes the labor intensity of workers. For example, two workers operate two 6-head machines, which is equivalent to 12 people operating 12 lock-stitch machines, which can directly save 10 skilled sewing machine operators for the enterprise. It can be seen that the benefits of “machine substitution” are quite objective, and the technological dividend far exceeds the demographic dividend.

The fourth generation sewing machine (4-head machine) at the Guangzhou Garment Machinery Exhibition

Computerized rivets Nailing machine

The machine does not stop and the efficiency is doubled

The fourth generation sewing machine – “zero waiting” model: AB format alternately sews, the machine head does not stop, no need to move the template; the efficiency is maximized and the operation is the most simplified. A+B fit, super large 2.5 meters width, efficient sewing of any product. One machine with multiple heads, easy operation, automatic production, excellent quality and complex processing. The automatic sewing of super large format products is realized, which greatly improves the adaptability of the sewing machine. Industrial software programming and industrial control technology control the sewing trajectory, freeing human hands while realizing precise and complex sewing. It breaks through the limitation of the sewing area of the arm sewing machine, and can fully grasp the material, making the seam more accurate, and the sewing process is intelligently controlled.

Automated Leather Punching Machine

The stitches are exquisite and ingenious

The fourth-generation sewing machine is used for sewing stitches: the pattern program is edited by computer, the sewing is intelligently variable speed, and the sewing process is fully automatic computer control. The stitch file corresponding to the template is automatically recognized, which improves the sewing stitch accuracy and facilitates operation. Sewing function: automatic cycle sewing, pleated sewing, thick material sewing, multi-layer sewing, arc polygonal sewing with various patterns; it also has embroidery function, buttonhole opening and pocket cutting, collar pocket cover clean Edge, gradient stitching, mark identification function, broken thread detection function, backstitch re-thread function; automatic template positioning, automatic reading, automatic start of sewing and many other functions.

Widely used and generally welcomed

The fourth-generation sewing machine is widely used. Suitable for down jackets, shoes and hats, clothing, car interiors, gloves, bulletproof clothing, child seats, sleeping bags, cotton clothing, luggage, shirts, work clothes, school uniforms, etc. Taking traditional down garments as an example, in the past, they were all simple straight lines, and they needed to be marked in advance, and the sewing was completed by skilled lathes, and the pass rate was difficult to guarantee. Now: the use of template sewing technology can enrich and beautify the appearance design of down jackets, and add functional designs such as radial lines, corrugated lines, and gradient spacing. In the past, in the production process of traditional manual sewing control, it was difficult to control the curve and spacing; now it can be done very easily with a fully automatic sewing machine combined with the template process.

Contrast: Traditional sewing machines in old garment factories: one person, one machine, low efficiency

Eyelet Sewing Machine

Social benefits of the fourth-generation sewing machine

The fourth-generation sewing machine is designed with computer software to precisely control the stitch length and the number of stitches. There is no error in the number of stitches or stitch length caused by the operation of different sewing workers, so as to ensure the stable quality of garment sewing. As long as the operator’s operation is compliant and operates according to the determined process, 100% qualified products will be sewn. The cutting pieces and sewing information of the fourth-generation sewing machine are all in the sewing file. The machine is automatically identified and sewn, and the sewing process and results are traceable and recordable, which makes automatic data collection easy. .

The fixtures used in the fourth generation of sewing machines will develop from a single flat template to ever-changing special fixtures to meet the requirements of different sewing materials and different sewing product processes. Directly sew multi-layer fabrics and clips, then cut them, and finally sew into garments, “sew first and then cut”, completely subverting the traditional garment manufacturing process.

Automated pattern sewing machine

The application of the fourth-generation sewing machine is like a modern general machining factory using a CNC machining center, and other sewing equipment will be configured around the needs of this sewing machining center. It is foreseeable that the main equipment of a garment enterprise in the future will be automatic sewing equipment represented by the fourth-generation sewing machine, which has changed the previous experience routines such as equipment ratio, equipment placement, and equipment use. Due to the extensive use of fourth-generation sewing machines, it will inevitably lead to the adjustment or transformation of the processes and plans of people, machines, and objects in the entire enterprise.

The integrated production line with the fourth-generation sewing machine as the main node will organically link the design, plate making, cutting, clothing, feeding, feeding, discharging, sewing, garments and other processes, simplifying the labor links, Establish an Internet channel, realize flexible manufacturing, and truly respond quickly to market demand.

The fourth-generation sewing machine is widely used and will become the main sewing equipment for garment enterprises. Drive all the equipment in all aspects of clothing production to be controlled by computer and networked, so as to realize the comprehensive information management of the enterprise. The fourth-generation sewing machine promotes the deep integration of industrialization and informatization in China’s garment industry in terms of technology, products, and business, and brings a good start to the comprehensive realization of computerized clothing design, production automation, management informatization, and intelligent production. The horn of sewing machinery industry 4.0 is sounded from here. The future of the fourth-generation sewing machine is also the future of our garment industry.

[/av_textblock]

[/av_one_full]