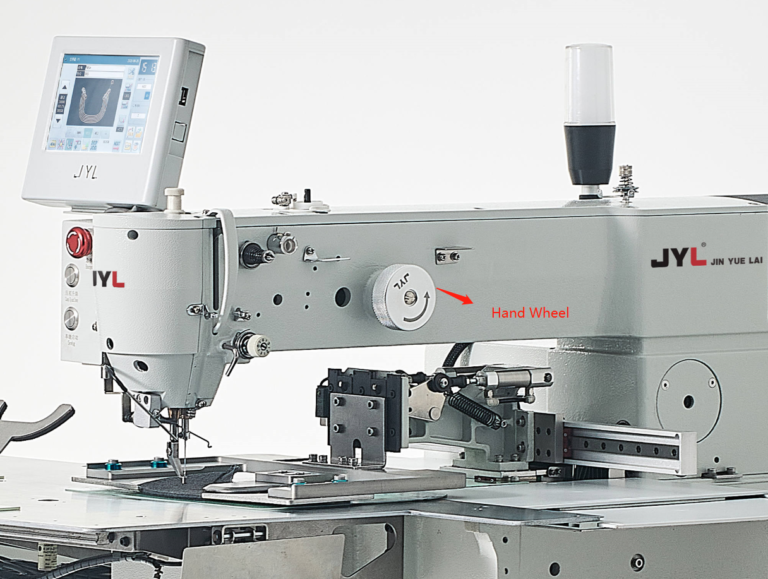

What Is A Hand Wheel On A Sewing Machine?

Hand Wheel is also called a driving wheel (UK), or simply wheel) is a type of steering control in vehicles. And it is also known as balance wheel for the sewing machine. It is a round wheel located at the upper right of the sewing machine. it’s : The Hand Wheel (It’s bumped on the right side of the sewing machine. “The Main purpose of Hand Wheel used for a sewing machine is to slowly turn the needle by hand. Many sewing machines allow their feed dog to be disengaged for hand controlled sewing processing such as for quilting or mending. The balance wheel manually advances the sewing machine.The balance wheel should only be turned in the direction that advances the sewing machine—never in the opposite direction. Turning the balance wheel in the opposite direction could ruin the tension on your machine or tangle the thread. The balance wheel is usually used to sink the needle before you start a seam, or to raise the needle once you have finished a seam.

What Is The Hand Wheel For A Sewing Machine? It is a round part located at the upper right of the sewing machine. And it can help to adjust the speed of needle stitching.

Hand wheels, when specified, should be mounted and designed to operate in the following manner.

- For globe valves, handwheels should be mounted on the yoke, arranged so that the valve stem can be jacked in either direction.

- Neutral position should be clearly indicated.

- Handwheel operation should not add friction to the actuator.

- Clutch/linkage mechanisms for handwheels on rotary valves should be designed such that control of the valve position is not lost when engaging the handwheel.

On most modern electric sewing machines the hand wheel (that “bump” on the right side of your sewing machine) is turned toward you (counter-clockwise if you are looking at the sewing machine from the right side of your machine) to take a manual stitch.

The times you use the hand wheel to make a stitch include when you want to turn a corner on your project (called a pivot) and you need the needle in the fabric to do this. So…you turn the hand wheel toward you till the needle is in the fabric, lift up the presser foot and turn your work. Then you put the presser foot down and continue to stitch. Another time you need to use the hand wheel is if when you come to the end of your stitching if the take-up lever is down. You need to turn the hand wheel until the take up lever is in the topmost position in order to complete your stitch. Another time you use the hand wheel to stitch a manual stitch is at the end of a dart. I will talk about dart construction in more detail in a later blog post, but this is an important instance of using the hand wheel to make a manual (non-electric) stitch.

Side-mounted hand-wheels should be chosen for valves at higher elevations.

The side-mounted hand wheels may also be operated by a chain fall plus chains to release and rest the locking levers.

Both of these operators can be used to facilitate the start-up of a control system. They can also be used as devices to shut off the valve, eliminating the need in some systems for costly bypass valve arrangements.

The actuator should be equipped with a permanently attached handwheel of the automatic declutching type that precludes mechanical engagement of the sewing machine handwheel while the drive is in operation.

The declutching device should:

Hand wheel drive should permit the valve to be stroked open or closed in 15 minutes or fewer.